|

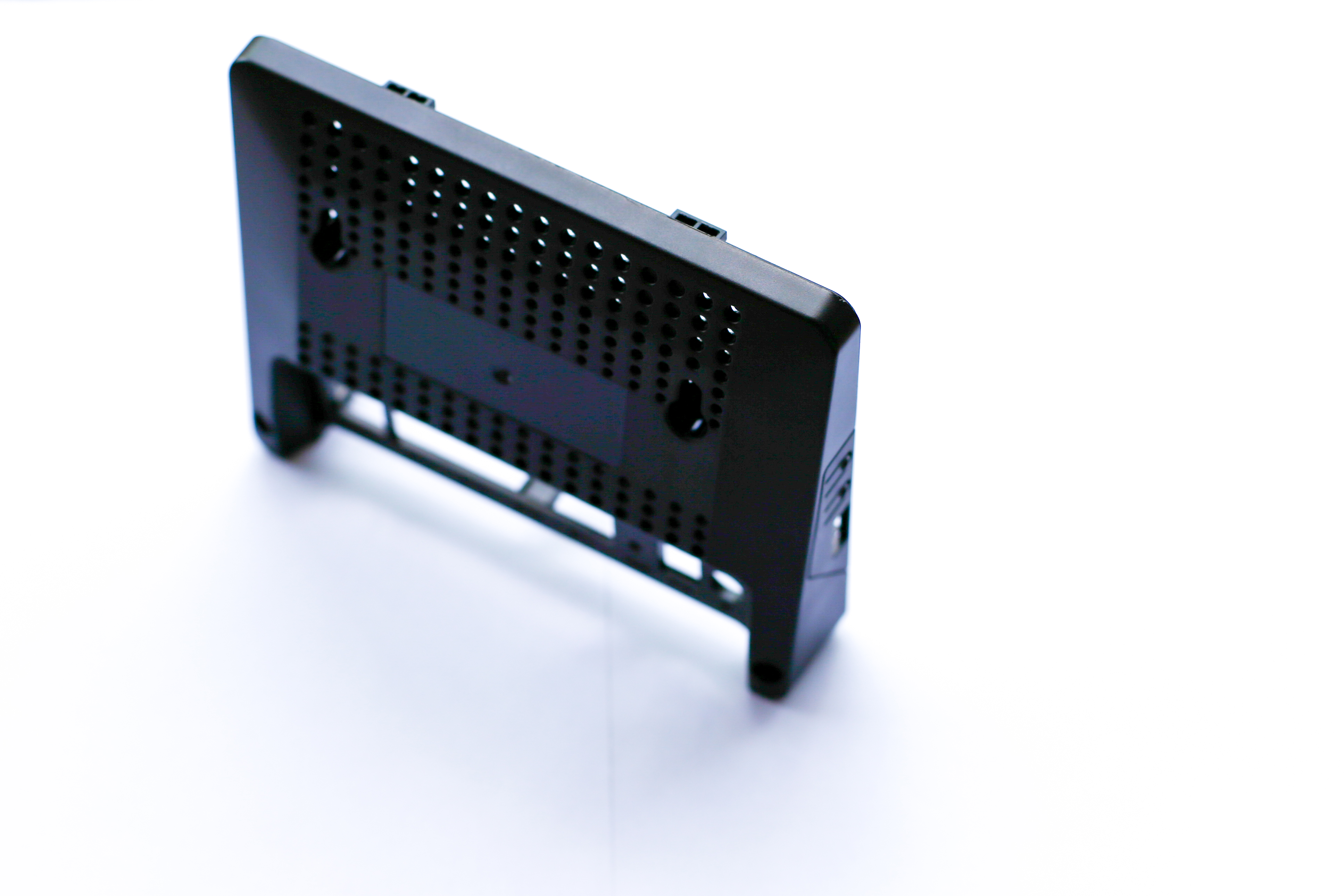

Why “Thin to Thick” causing a problem?

The thicker section of the molding requires more packing, i.e. it needs more time to fill. Hence, when the gate is place at the thinner section, as shown in Fig.1, the transition area between thick and thin would freeze off before the melt fully fill the thicker if the flow length is large. Also, the melt would tend to jet when it first enters the thicker section and cause bad surface finishes.

|

|

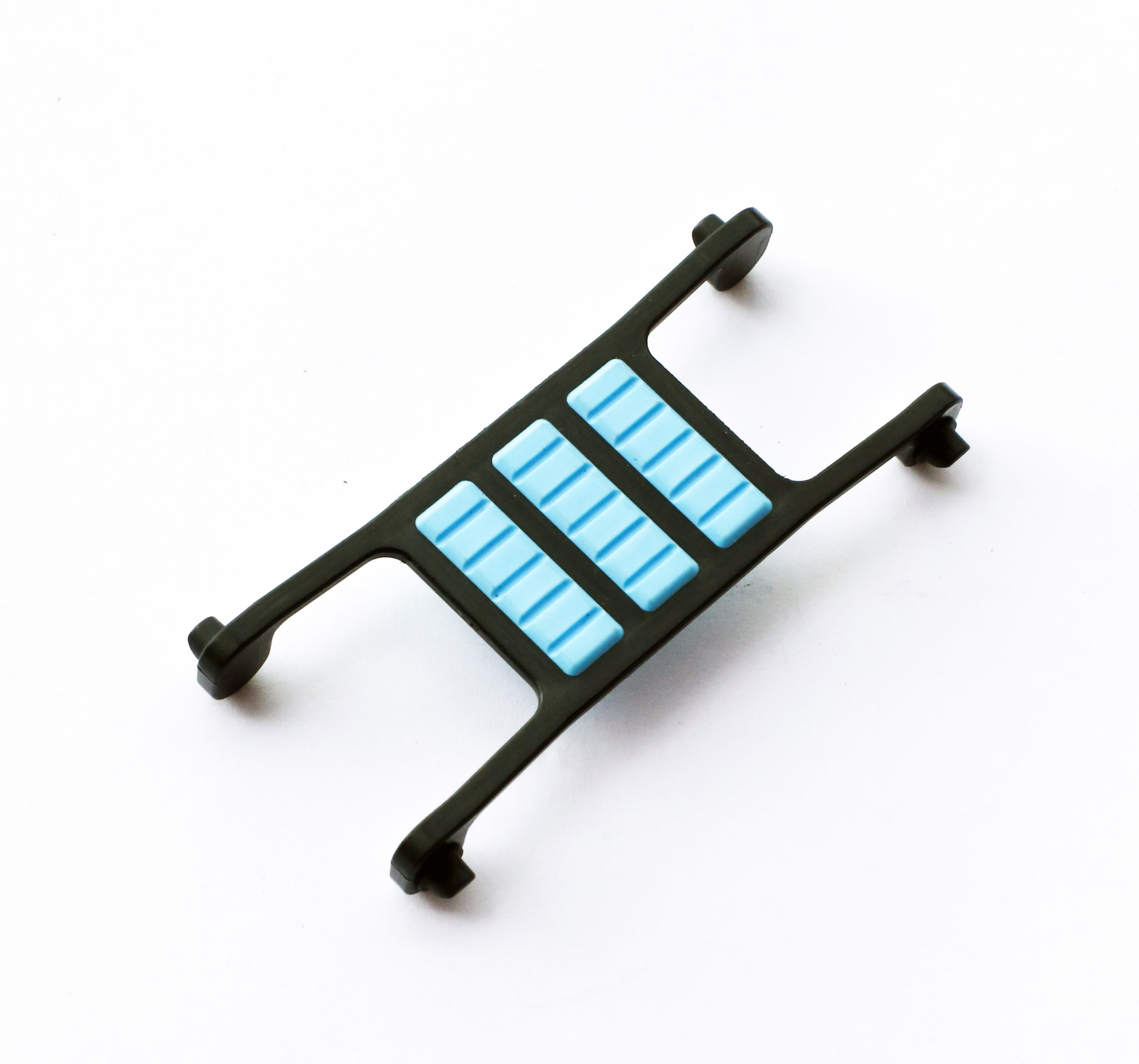

“Thick to Thin” also Problematic

However, blindly applying general rules is not wise. “Thick to thin” also cause problems in some scenarios. Considering an edge gate shown as in Fig.2, jetting occurs as the melt stream into the open cavity and result in a poor appearance. Jetting would also lead to poor strength as the melt weld not well.

|